To evaluate alternatives for meeting energy demands and to make sound decisions about large capital expenditures for plant additions and alterations, facilities managers need a basic understanding of heating and power plant cycles and equipment. This chapter discusses central heating and power plant fuels, processes, and equipment. Details on fuels, fuel firing, boiler and emission control, and operation apply generally to all boiler sizes and types. Boilers are the basic building blocks of a system for generating hot water (for direct heating) or steam (for generating electricity, heating and cooling, and processes) and are used by almost every university in a central plant or in buildings as distributed package boilers. Auxiliary equipment is available to maximize use of heat generated in fuel burning, increase plant efficiency, and satisfy emission standards. Reliable plant system performance and efficient energy delivery are equally important; utility operating expenses not uncommonly approach one-half of the facilities budget.

Central Systems

Basic power plant cycles and configurations for steam or hot water distribution in a central plant system have economic and operational advantages, such as less required capital; lower total install load (diversity factor); more effective central standby equipment; reduced in- building machinery space needs; economically feasible 24-hour skilled operator supervision; centrally concentrated noise; minimized operation and maintenance (O&M) staffing costs; increased efficiencies with large equipment; much improved part- load performance efficiencies; single point of delivery (and better rates); practical multiple fuel sources; efficient boiler staging for variable loads and coincident peak load responses; and fewer standby units, reducing maintenance. Disadvantages are high initial costs, thermal and hydraulic losses, more stringent environmental regulations, and Canadian provincial legislation and regulations.

Fuels

Central plant boilers use diverse primary fuels (e.g., natural gas, fuel oil, coal), augmented by alternate fuels (e.g., refuse-derived fuel, tire-derived fuel, wood products, petroleum coke, anthracite culm, manufacturing byproducts). Each fuel must be evaluated based on availability and price (as delivered to point of use), transportation charges, fuel impurities, and variability in higher heating value of fuel (in Btu per pound). Normal heating values for fossil fuels fall in ranges (Figure 3.5).

Figure 3.5. Normal Range of Heating Values for Various Fossil Fuels

| Methane | 23,811 Btu/Ib |

| Propane | 21,564 Btu/Ib |

| Natural gas | 20,000–23,500 Btu/Ib. (1,000 Btu/cu. ft.)* |

| No. 1 fuel oil | 19,670-19,860 Btu/Ib |

| No. 2 fuel oil | 19,170-19,750 Btu/Ib |

| No. 4 fuel oil | 18,280-19,400 Btu/Ib |

| No. 5 fuel oil | 18,100-19,020 Btu/Ib |

| No. 6 fuel oil | 17,410-18,990 Btu/Ib |

| Bituminous coal | 10,500-14,500 Btu/Ib |

| Sub-bituminous coal | 8,500-11,500 Btu/Ib |

| Lignite | 6,300-8,300 Btu/Ib |

| Anthracite culm | 4,000-5,000 Btu/Ib |

| Biomass Fuels (dry) | |

| Corn stock | 7,587-7,967 Btu/Ib |

| Wheat straw | 6,811-8,838 Btu/IB |

| Harwood | 8,017-8,920 Btu/IB |

| Softwood | 8,000-9,120 Btu/IB |

| Newspaper | 8,477-9,550 Btu/IB |

| * A Btu is equal to the amount of energy required to raise the temperature of 1 lb. of water 1°F. | |

| ** one Btu equal 1.055 Kj | |

Principles of Combustion

All fuels combust by combining oxygen with carbon and hydrogen (oxidation) to release heat, carbon dioxide, and water. When a lack of oxygen results in incomplete fuel combustion, carbon monoxide (itself a fuel) is formed.

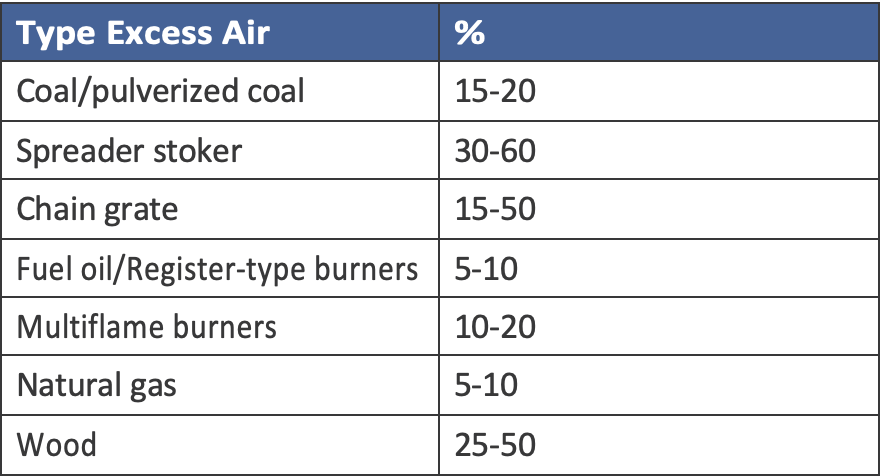

Combustion products also can include nitrogen and sulfur oxides (regulated pollutants). The three conditions for combustion (basic equation in Figure 3.6) are gasified fuel, oxygen-fuel mixture in the flammable range, and a mixture above its ignition temperature. Combustion quality is determined by time, temperature, and turbulence (a key factor). The specific amount of air required to complete combustion is theoretical air; in actual combustion, excess air (a primary system performance indicator) is also required, with amount based on boiler type, fuel properties, and burner or stoker features. This section explains calculating excess air requirements as a percentage (Figure 3.7 shows typical ranges).

Figure 3.6. Basic Combustion Equation

| -I-02 + N2 + S C02 + N2 + SOx + HEAT |

| Air Impurity Products Combustion (Sulfur) ash |

Figure 3.7. Typical Ranges for Excess Air Fuel Combustion

Figure 3.8. Central Heating Plants Fire Tube Boiler

Boiler Types

Boilers come in two types, fire tube and water tube, and are further classified as either package units or field- erected units (based on manufacturing method and installation).

Fire Tube Boilers. These boilers have ratings (usually in horsepower), simple and rugged construction, and low initial cost. They operate sluggishly and are slow to achieve operating pressure from a cold start. Several operational configurations (two-pass, three-pass, four- pass) are used based on number of times hot gases are routed through the boiler shell; additional passes increase initial cost and unit efficiency (see Figure 3.8).

Boiler Life. Regular specialized maintenance (e.g., monitoring fuel-air ratio and safe burning) is required for any boiler (in general, daily, monthly, and annually), but more often for oil than gas-fired burners.

Water Quality. Especially for steam boilers, regular surface (typically automatic) and bottom (typically manual) blowdowns are needed to prevent buildup of solids. For hot-water boilers, a shot feeder usually introduces the chemicals, but once treated properly, such systems require little maintenance. For steam boilers, typically automatic feed systems introduce chemicals in makeup water, often in conjunction with blowdown. Boiler water treatment is highly specialized and best left to experts.

Life-Cycle Cost. Boiler power is based on required steam mass flow rate, pressure, and temperature. Input fuel quantity depends on fuel energy content and overall energy efficiency. New boilers running on coal, oil, natural gas, and biomass can reach efficiencies of 85 percent, 80 percent, 75 percent, and 70 percent, respectively. Preventing or recovering heat loss improves boiler efficiency. Fuel costs account for 96 percent of steam generation system costs over the boiler life cycle. The initial cost of a water tube boiler is higher than that of an equivalent fire tube boiler, but efficiency is much higher, and performance responds better to load changes. Water tube boilers are package units if small but field erected if large.

Boiler Inefficiencies

Three factors can inhibit heat transfer to steam and water in the boiler, resulting in lost energy.

Combustion Factors. Combustion losses are in three categories. (1) Flue gas waste heat has two forms, dry gas loss and moisture loss, that are lowered by reducing excess air to a minimum (via better mixing of fuel and air) and increasing heat recovery. Care must be taken in boilers with economizers, air preheaters, and other auxiliary equipment because reduced stack temperatures can lead to water vapor condensation that combines with sulfur to form a corrosive acid. (2) Combustible losses (i.e., incomplete combustion) are evidenced by solid combustibles in ash, carbon carryover in fly ash, carbon monoxide in exhaust gas, and unburned fuel.

Heat Transfer Factors. Deposits inside and outside heat transfer tubes act as insulators, impeding heat transfer. Several steps can counteract buildup (e.g., for water tube boilers, frequent soot blowing, perhaps three times a day; water-side deposit control via water treatment and mechanical or chemical cleaning).

Steam Loss Factors. Steam losses result from faulty steam traps (probably most significant), drain and vent leaks to the environment, and inadequate steam line insulation. Many tools detect faulty traps (e.g., temperature-indicating crayon, temperature-actuated color-changing tape, surface temperature gauges, ultrasonic detectors). Pipe insulation is based on cost- effectiveness (at steam line installation), but energy cost increases can change the incremental cost-benefit relationship, making insulation cost-effective.

Power Plant Auxiliary Equipment

Auxiliary equipment (e.g., most commonly heat exchangers) can be added to recover heat and increase overall boiler system efficiencies, normally by 3 to 8 percent. Each installation is unique, so this section does not quantify potential savings from adding auxiliary equipment, but such analysis must consider equipment configuration, steam characteristics (pressure, temperature), purchased power costs, and fuel costs.

Qualified engineers must study each power plant to assess efficiency improvements.

Economizers. The most common auxiliary, economizers transfer hear from flue gases to boiler feedwater. Most economizers operate at low temperature, with a large heat exchanger surface area.

Pollution Control Equipment

Increasing numbers of federal, state, provincial, and local environmental regulations govern power plant emissions, varying by region but likely applying to any major plant addition or modification.

Mechanical Collectors. Mechanical collectors control particulate emissions by changing gas stream velocity and direction to allow heavier particulates to fall into a hopper. They collect large amounts (as much as 90 percent) of all particulates, often in series with other pollution control devices. They have no moving parts but require cleaning maintenance, with efficiency depending on particle size and weight.

Electrostatic Precipitators. Electrostatic precipitators often are used when collection efficiencies of 99 percent or less are needed. Performance is a function of coal chemical constituents and fly ash electrical characteristics. Efficiencies are notably higher when burning higher sulfur coals.

Bag Houses. One of the most efficient methods, bag houses remove more than 99 percent of particulate matter and are smaller and cheaper than a comparable precipitator. When the pressure drop across the bag house reaches a predetermined level, the bags are cleaned (ash cake on the fabric acts as a filter, so maximum collection efficiency occurs immediately before fabric filter cleaning).

Scrubbers. Federal, state, and local environmental regulations require most new boilers to limit gaseous emissions, usually sulfur (most prevalently sulfur dioxide) and nitrogen but also trace elements, heavy metals, organic compounds, and other toxic emissions. Sulfur oxides can be controlled by removing sulfur before or during combustion. Scrubbers are the primary method of removing sulfur from boiler exit gases. (1) Wet scrubbers are characterized by high water use, large waste material quantities, high operating costs, and an atmosphere like a wet cooling tower. They can remove nearly 90 percent of all sulfur oxides. (2) Dry scrubbers (e.g., spray dryer systems, fixed absorbent beds) minimize water use, do not require waste drying, and can use a dry fly ash conveying system to handle generated wastes.

Compliance Equipment. Gas analyzing equipment might be added to the boiler to comply with state, provincial, federal, and local emission restrictions.

Equipment complexity and reporting requirements depend on the regulating agency. Opacity monitors measure particulate emissions from a specified source; continuous emission monitors (in situ, extractive, dilutive extractive) are often required after any major plant modification or addition, extensively analyze the flue gas stream for gaseous emissions; and ambient dust monitors are sometimes required for fugitive dust emissions in the sub-10-micron range.

Boiler Performance Troubleshooting. Combustion- related problems include high exit gas temperatures, high or low excess air quantities, and high carbon monoxide and combustible emissions.

Boiler Efficiency Improvements. This section lists energy recovery systems, heat transfer strategies, and efficiency improvements for economizers, recuperative (tube type) or regenerative (rotary type) air heaters, closed or open (commonly deaerator) feedwater heaters, radiant and convection superheaters and associated desuperheaters, and blowdown heat recovery to capture high heat loss during blowdowns.

Ash Reinjection. Complete combustion is not possible, so unburned carbon in the fly ash (from 1 to 20 percent) is entrained in flue gas exiting the boilers, dramatically affecting boiler system efficiency. Ash reinjections capture this fly ash and unburned carbon for reintroduction into the combustion zone.

Combustion Additives. Fuel oil and coal are not homogeneous in impurities and physical characteristics; combustion additives improve fire-side efficiency by increasing reaction rate and lowering reaction temperature, with the collateral benefit of reducing particulate emissions (e.g., in stoker-fired boilers).

Turbines

Steam Turbines. Steam turbines receive high-pressure, high-temperature steam from the boiler and use pressure and temperature reductions to convert thermal energy to mechanical (shaft) energy (e.g., to drive a generator, chiller, fan), with steam expansion in one or more turbine sections connected to a shaft.

Turbine Efficiency. Heat engine efficiency relates to temperature, which in turn relates to pressure. The basic formula indicates that the larger a change in temperature (by increasing inlet temperature and pressure or by lowering exhaust temperature and pressure), the more efficient the engine. Lowering exhaust temperature and pressure is generally more feasible, but steam must not condense in the turbine.

Types of Turbines. (1) Back-pressure turbines exhaust at or above atmospheric pressure and are typically used in cogeneration. (2) Condensing turbines (whether controlled extraction units or straight condensing units) lower exhaust pressure, retain treated feedwater, collect it in a hot well, and pump it back to the boiler. (3) Gas turbines have three main sections (compressor, combustor, turbine) and often run on natural gas or fuel oil. They have short lead times and low capital costs, come online quickly, and can resolve backup power or peak shaving issues. Some control method is required to control the NOx pollutant; (e.g., water or steam injection into the combustor; selective catalytic reduction).

Condensers. Condensers might be required if connected loads do not use all produced steam. These heat exchangers transfer turbine exhaust heat directly to the atmosphere or to a cooling water stream for release to the atmosphere. Condensers generally handle large heat quantities and differ in how they release heat to the atmosphere. The major condenser types are once- through cooling, cooling pond, spray pond, natural draft evaporative cooling, mechanical draft evaporative cooling, and dry cooling towers.

Chemical Treatment

Capital boiler investment is protected by reducing scale formation, metal corrosion, and solids carryover.

Boiler Water Treatment. Pure water is an active solvent, picking up or dissolving part of everything that it contacts, but impurities in water can cause scale, corrosion, and carryover in the boiler. Most boiler feedwater systems are treated with chelant and polymer-type chemicals (not phosphates, as previously), and keep such impurities in suspension; and contain a deaerating feedwater heater; and add hardness- controlling and degassing chemicals in the blowdown system.

Water Treatment

Centralized heating plants consume large amounts of water. Many local water systems cannot meet such demand, so heating plants must operate water treatment plants. Depending on raw water source, a water plant can use a wide range of equipment and systems to develop potable water for direct use in chilled water and cooling tower systems, but purifying water further for boiler use requires additional processing, such as using (1) condensate polishers to control contaminants (e.g., iron, copper, sodium, chloride, silica, calcium, magnesium); (2) zeolite softeners to address dissolved solids simply and economically, but producing high-alkaline water; (3) demineralizers to soften water, producing better quality water for boilers than any other method, but with much higher initial capital costs (and water that cannot be used in other applications because of high mineral scavenging characteristics); or (4) reverse osmosis to pretreat boiler water and remove impurities via a selectively semipermeable membrane, usually more costly to operate and install than comparable demineralizers, but without chemicals and with fewer waste products.

Water Plants. Water treatment equipment (e.g., aerators, flash mixers, flock tanks, settling basins, clarifiers, lamella filters, gravity filters, pressure filters, chlorinators and chemical feed equipment) and configurations for producing potable water can vary dramatically by raw water source (e.g., wells, lakes, rivers), but the operating principles are the same.

Primary plant processes are clarification (removal of suspended matter and color) and sterilization (control of microorganism levels to a point lower than local regulatory standards, usually using chlorine). Water plant design depends on raw water source, potable water quality goal, design and emergency flow rates, and available equipment space.

Control Systems

Combustion controls adjust the fuel supply to maintain required steam flow or pressure under different loads and to maintain the optimum ratio of combustion air to fuel. The three basic control system types are (1) on-off, used only for fire tube and very small water tube boilers;

- positioning (fixed, parallel with operator trim, or pressure ratio), used on single-burner boilers and restricted to systems that burn one fuel at a time; and

- metering, restricted to fuels that can be accurately monitored, with refinements such as cross-limited metering and continuously monitored flue gas analysis. Most boilers now are controlled by flexible, responsive, dynamic, and easily tuned microprocessors. Using more complex control strategies requires highly skilled onsite design and maintenance personnel but often realizes higher system efficiencies and fewer forced outages. Retrofitting a microprocessor control system for in-place pneumatic or analog-type controls can recover costs quickly with multimillion-dollar annual fuel

Monitoring and Controlling Performance

All steam and hot water generators should be performance tested before heating season and after annual water-side, fire-side, and control system maintenance and inspections. Using this base, the operator can monitor central heating system performance by regularly reviewing and as needed adjusting fuel-to-steam conversion efficiencies; evaluating water makeup quantities; and reviewing stack gas temperatures. Personnel must have instrumentation and written operating instructions.

Hourly rounds record machine status, operating temperatures and procedures, and meter readings if flow rates are available. If stack gas oxygen content and boiler water status are not continuously indicated, at least twice a shift, readings must be manually analyzed and recorded. Supervisors must reinforce routine and accurate operating parameter recording to identify causes of plant performance efficiency losses. Annual performance testing must be conducted for plant auxiliary equipment (e.g., pumps and drives, deaerating feedwater heaters, operating instrumentation and controls, steam traps, valves, makeup water softeners, auxiliary heat exchangers, stack gas cleanup systems).

System Retrofit Possibilities

Many field retrofit options can improve efficiencies and reduce operating costs (depending on fuel prices), including retrofit economizers to replace a section of boiler exhaust ductwork, gas and oil burners that operate at excess air levels as low as 3 percent and have good turndown, boiler blowdown heat recovery via a small heat exchanger, microprocessor-based controls, and piping insulation.

Create an Account

Create an Account

Login/myAPPA

Login/myAPPA

Bookstore

Bookstore

Search

Search  Translate

Translate

Leave a Reply

You must be logged in to post a comment.